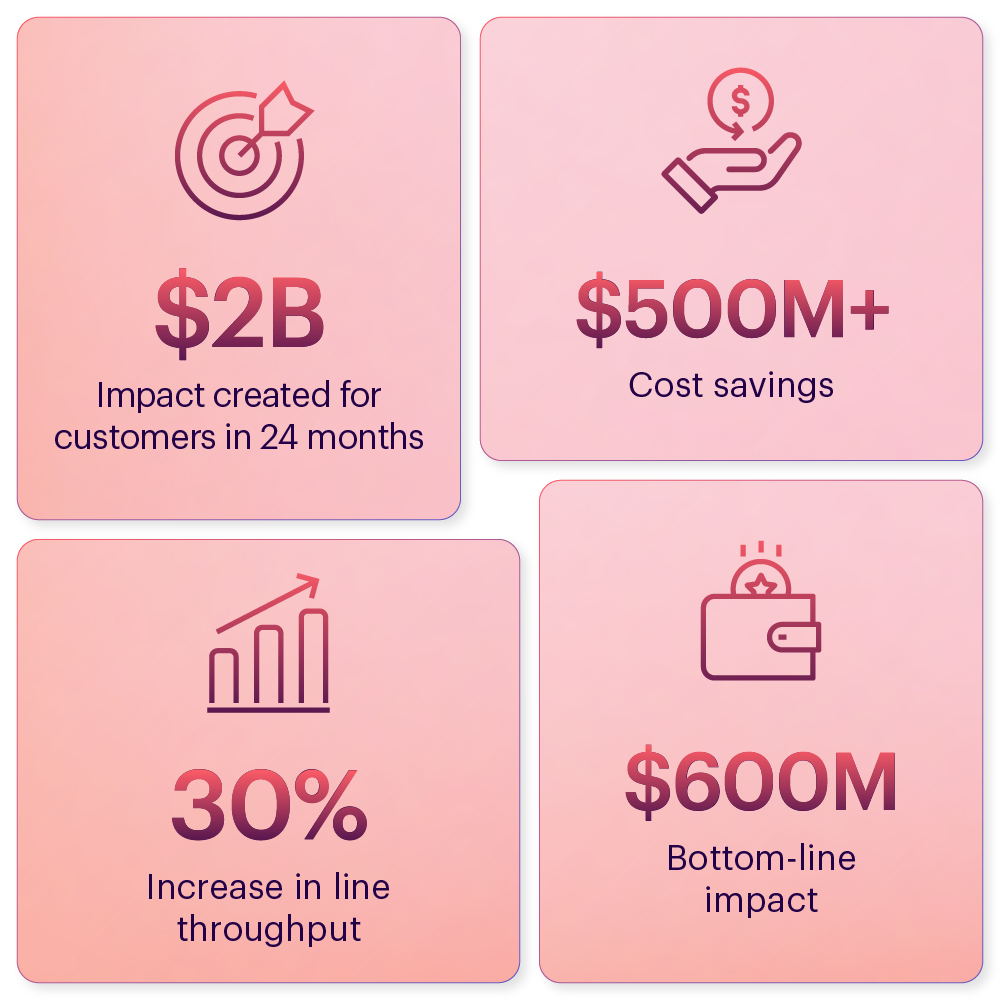

At MathCo, we help manufacturers turn data, the backbone of modern manufacturing, into a competitive edge by streamlining operations, boosting efficiency, and future-proofing their businesses. Our analytics solutions are transparent, explainable, and adaptable, helping clients respond to market shifts with confidence. By integrating data from every digital and physical touchpoint, we deliver insights that drive real, measurable impact.

Digital twins play a pivotal role in enhancing functional efficiency by optimizing factory configurations and reducing downtime. Leveraging their potential helps businesses achieve faster and better outcomes. At MathCo, we use simulation and emulation of real-world processes to analyze and optimize key parameters. Our capabilities empower clients to improve the effectiveness of experimentation through digital simulation, enabling significant cost savings and higher success rates through simulated testing.

Predictive maintenance has harnessed data to improve equipment performance and reduce downtime, enabling businesses to streamline operations and accelerate processes. By unearthing latent insights through machine data, we capture maintenance issues in advance to reduce the negative impact on throughput and breakdowns. These are further integrated through machine interfaces to drive consumption in real-time.

Identifying the right vendor who can innovate and evolve at the industry’s pace plays a crucial role in helping manufacturing businesses grow at scale. At MathCo, we equip our clients with improved metrics and strategies to gain advanced insights. Based on true performance attribution, we develop optimal and effective vendor engagement strategies that positively impact businesses. We create optimized incentive and pricing protocols to increase conversion, top-line volume, and revenue impact.

A seamless and high-functioning supply chain is essential for manufacturers to grow beyond disruptions. An optimized supply chain can help businesses cut costs without compromising quality and efficiency. We aid businesses by developing accurate trend and sales forecasting models through market study and analysis. These activate practical insights for our clients, ensuring that they have complete control of their intelligence. We optimize inventory allocation based on projected sales to reduce lost sales and stock holding costs.

Effective workforce planning is critical for optimizing labor spend and closing talent gaps across complex operations. We enable organizations to analyze historical labor data, planned vs. actual hours and costs, in-house vs. vendor mix, and fulfillment KPIs across roles, regions, and time periods. Our driver-based forecasting models and scenario planners identify labor gaps and simulate the impact of key levers such as holidays, sabbaticals, cross-training, and hiring strategies. The result is a dynamic, optimized workforce plan that aligns capacity with demand, reduces reliance on external vendors, and enhances in-house talent utilization.

Optimizing production schedules in highly regulated environments requires intelligent orchestration of processes, quality controls, and real-time adaptability. We enable this through advanced optimization models integrated with existing tools like Infor to automate production and maintenance planning. Our solution leverages heuristic algorithms, real-time data pipelines, and reinforced learning to generate schedules that reduce quality violations and enhance operational efficiency. It adapts to shop floor changes, optimizes cleaning cycles, boosts resource utilization, drives faster decisions, and results in cost savings and reduced consumption of water, chemicals, and labor.

Revolutionize Your Business Growth with GenAI

Learn MoreKeep up with MathCo

Our Experience

Minimizing Unplanned Downtime with Predictive Maintenance in the Manufacturing Process

Discover how we helped a pharmaceutical manufacturer reduce critical equipment failures by 40% and save $1M annually. Through a scalable, cloud-based anomaly detection framework, we optimized maintenance, improved efficiency, and ensured compliance.

Read more

Optimizing Resource Planning with Predictive Intelligence and Scalable Automation

Discover how MathCo helped a global leader in electrification software optimize workforce planning through predictive insights and intelligent automation, reducing costs, improving efficiency, and enabling strategic scalability.

Read more

Enabling Data Trust and Efficiency in Manufacturing Through Master Data Management

Discover how we helped a leading manufacturing company overcome inefficiencies caused by fragmented data, duplicate records, and weak governance. Through our comprehensive MDM framework, we optimized data integrity, security, and integration, enabling streamlined operations, improved customer profiling, and better decision-making for long-term efficiency and growth.

Read moreMeet Our Experts

Take the next step towards excellence with our leaders