In an era of rapid technological advancement, the intricate domain of pharma logistics faces unprecedented issues. From slight undetected thermal deviation to delayed customs clearance, not only erodes multimillion-dollars, but also undermines stakeholders’ confidence. Today, the pharma industry loses $35 billion a year because of cold chain failures, compounded by significant escalations in global disruption expenditures since the onset of geopolitical instabilities and climatic perturbations.

From increasingly fragile cold chains needed for biologics and vaccines, to navigating global regulatory variances and surging disruption costs, the challenges are no longer just operational, they are strategic. To overcome the losses, organizations are making a considerable number of investments in IoT infrastructure, dashboards, and monitoring tools. However, these systems plateau at observation, never transitioning to value creation.

MathCo believes that the future of pharma supply chains lies not just in simulation, but in measurable impact. Digital twins, when combined with AI and a quantified value framework, can transform supply networks from reactive entities into predictive, profit-saving engines capable of delivering both compliance and measurable ROI.

Bottlenecks Faced by Stakeholders Involved in Supply Chain

Organizations continuing with the traditional supply chain processes are struggling with inefficiencies and data silos that limit their end-to-end visibility. The major pillars of the pharma supply chain facing the issues are as follows:

- Manufacturing Operations: Struggle with unplanned downtime and yield loss

- Regulatory Teams: Require auditable traceability of processes

- Quality Assurance: Need proactive risk detection to avoid product recalls

- Logistics Partners: Face routing inefficiencies and compliance bottlenecks

- Commercial Teams: Lack financial visibility on operational decisions

Digital twins can plug these gaps by acting as simulators in real-time scenarios. However, in isolation, they remain merely simulation tools. When digital twins in supply chains are paired with AI algorithms for decision optimization, these models turn into time and cost-saving models.

AI enables proactive rerouting, spoilage avoidance, and scenario outcome ranking based on net financial gain rather than just operational feasibility.

Digital Twins in Pharma Supply Chain

In pharma supply chain management, digital twins are the virtual replica of the entire supply chain ecosystem enabling real-time insights of the product in transmission, thus helping in supply chain optimization. It includes modeling production plants, cold-chain containers, distribution nodes, and even individual vials.

Key Technologies Enabling Digital Twins

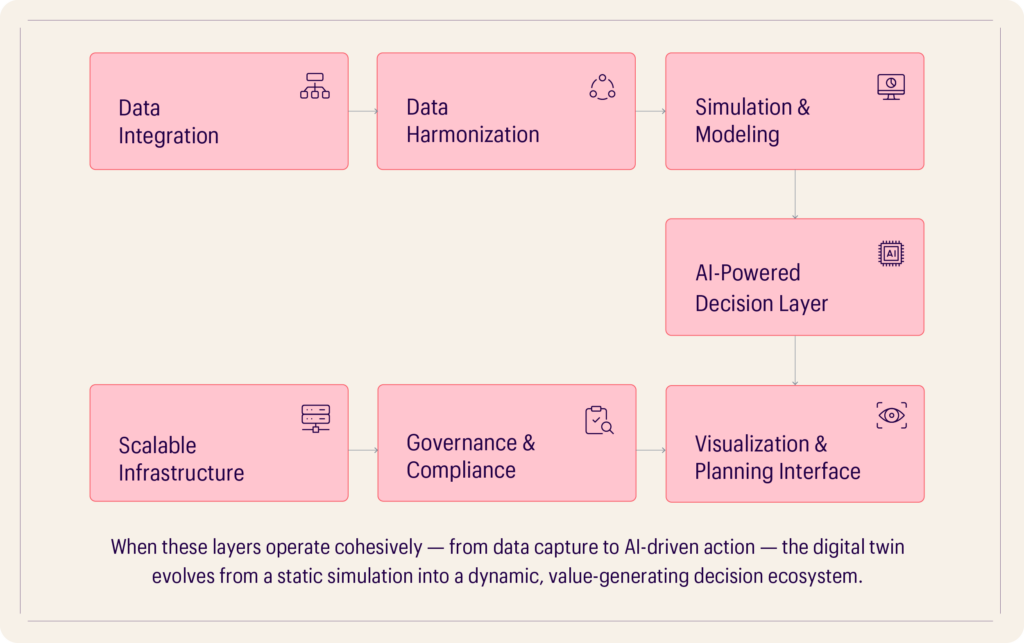

Multiple technologies are included to build a robust digital twin in pharma supply chains. The key components are:

- Data Integration

Data is the major component of any virtual system. The systems connect diverse data sources, viz., IoT sensors (temperature, humidity, GPS), core systems (ERP, MES, WMS, LIMS, QMS), and external variables (weather, logistics, geopolitical alerts), to enable end-to-end visibility. - Data Harmonization

The system establishes a unified data model that links product, location, quality, and time dimensions. Master data services support it to ensure consistency and reliability. - Simulation & Modeling

The platform uses thermodynamic, probabilistic, and network models to replicate real-world conditions — from temperature excursions and capacity constraints to disruption probabilities across supply nodes. - AI-Powered Decision Layer

The system uses reinforcement learning and optimization models to evaluate cost-benefit tradeoffs, predict outcomes, and recommend actions such as rerouting, expediting, or delaying shipments. - Visualization & Planning Interface

The interface equips planners with dashboards for scenario testing, sensitivity analysis, and AI-driven recommendations to support proactive decision-making. - Governance & Compliance

The platform implements robust audit trails, version control, and explainable AI frameworks to meet regulatory and quality standards. - Scalable Infrastructure

The solution leverages hybrid cloud-edge architectures for real-time processing, parallel computation, and continuous model updates.

MathCo’s Paradigm – Digital Twin-Enabled Analytics

At MathCo, we implement analytics-first digital twin framework, focused on measurable business outcomes. Leveraging our experience across industries, our approach extends beyond simulation by incorporating ROI measurement into every twin deployment.

Our Vision

- Analytics-driven architecture: We architect digital twins that combine operational data with advanced AI predictive models, ensuring measurable impact.

- Therapeutic-specific customization: We customize solutions to align with distinct regulatory and risk frameworks through our proprietary NucliOS platform.

- Unified data-product partner: Unlike traditional tech vendors, MathCo serves as a collaborative data-analyst partner, uniting AI, domain intelligence, and financial impact modeling.

- Transparency and scalability: Our solutions are integrated with regulatory documentation frameworks for compliance, thus supporting audit-readiness through continuous learning and feedback.

Our prior work in digital twin development for similar industries demonstrates our ability to generate real-time cost-savings reports, improve yield, and reduce downtime, thus making us ready for expansion into quantified AI-powered supply chain twins.

A Call to Pharma Leaders

Pharma leaders must move beyond simulations to quantifications. While investments in cold-chain infrastructure surpass $21 billion yearly, persistent silos in data governance and a lack of prediction leave organizations navigating ambiguity rather than mastery.

The need for the hour is to amalgamate digital twins with AI into a quantifying framework, to not just prevent spoilage but also to reroute the capital allocation to strategic corridors. The supply chains should be seen as a strategic asset rather than a cost-centric operation. Interested in learning how MathCo can help you with digital twins? You can learn more about our offerings for the Pharma industry here or contact us at [email protected]!