Manufacturing is the operational core of any enterprise. While strategic and commercial decisions define direction, manufacturing converts plans into reality. Unlike many other business functions, manufacturing operates in an environment where stability, precision, and compliance are paramount. Systems are rigorously tested, processes are tightly governed, and experimentation is limited by the risk of operational disruption.

In such an environment, scheduling plays a critical role in determining efficiency, responsiveness, and overall performance. This article explores the inherent complexity of manufacturing scheduling, the limitations of existing planning solutions, and how AI-powered scheduling optimization can enhance decision-making while working alongside existing manufacturing systems.

The Complex Landscape of Manufacturing

Every function within an enterprise has its own nuances and challenges. However, manufacturing is complex and critical like no other. It brings together business plans, operational constraints, and real-world execution on the shop floor.

Manufacturing environments are characterized by:

- Multiple and often disconnected data sources

- Localized processes and site-specific constraints

- Complex machinery with strict operating and safety protocols

- High sensitivity to downtime, changeovers, and compliance risks

Given this context, manufacturing systems are not designed for frequent experimentation. Teams are constantly cautious to ensure that even incremental changes do not disrupt production. This combination of operational rigidity, data fragmentation, and process complexity creates a challenging problem landscape—particularly when it comes to planning and scheduling.

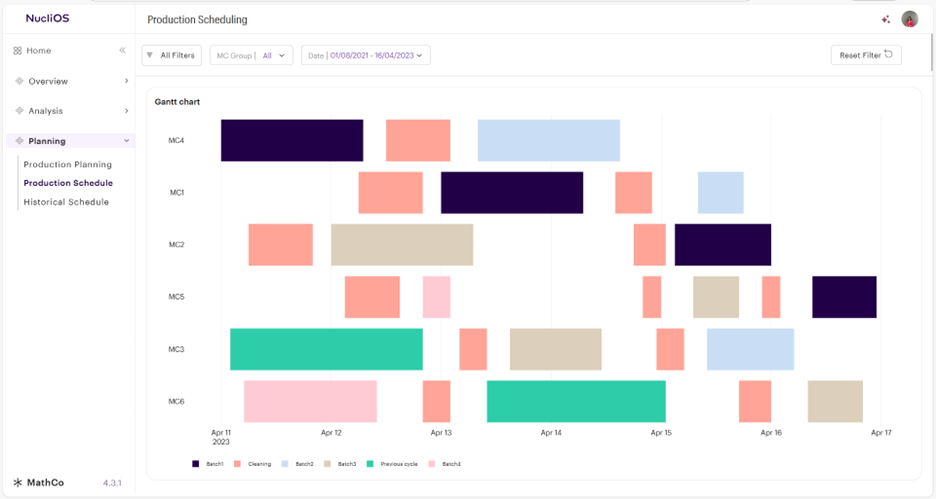

The Art of Scheduling

Scheduling is a foundational input into manufacturing operations. Decisions related to:

- Changeovers and sequencing

- CIP (Clean-in-Place) cleaning cycles

- Resource and workforce allocation

- Equipment availability and utilization

These have a direct and measurable impact on throughput, cost, quality, and service levels.

Traditionally, schedules are derived from large volumes of historical data, trends, and seasonality patterns. However, manufacturing environments are inherently dynamic. Demand fluctuations, supply constraints, unplanned downtime, and workforce variability continuously alter operating conditions.

As a result, schedules often need to be modified based on the latest and most likely scenarios. Planners and scheduling managers face a demanding task—balancing stability with responsiveness—while operating within tools and processes that are not designed for frequent re-optimization.

Limitations of Existing Solutions

Most existing scheduling and planning ERP systems are designed for stable, business-as-usual (BAU) scenarios. While effective for executing predefined rules and constraints, they lack the agility required to adapt to continuously evolving conditions.

Common limitations include:

- Static configurations that require manual intervention to update

- Limited ability to learn from historical schedule outcomes

- Inadequate support for scenario-based planning

- Poor integration of non-standard or external data sources

Addressing these challenges requires an approach that can learn from past behavior, abstract patterns, and modify scheduling decisions continuously—not as a one-time configuration, but as an ongoing process. Traditional software platforms are not built with these capabilities, presenting a significant opportunity for improvement.

MathCo’s AI-Powered Scheduling Optimization

MathCo designed an AI-powered scheduling optimization solution that enhances decision-making without requiring changes to the underlying manufacturing systems. This design choice was intentional, recognizing that technology change management in manufacturing environments is complex, time-consuming, and risky.

The solution is positioned to complement existing ERP and scheduling platforms, rather than replace them—adding an intelligent optimization layer on top of established processes.

Core Capabilities

The solution leverages accelerators and AI agents to:

- Read and integrate information from multiple, heterogeneous data sources

- Extract historical patterns and insights from past schedules

- Incorporate manufacturing protocols and regulatory requirements

- Dynamically adjust schedules based on changing operational parameters

The optimization layer is powered by Mixed-Integer Linear Programming (MILP) and multi-constraint programming frameworks, enabling the generation of optimized schedules under real-world constraints. Regulatory requirements—particularly critical in industries such as food and pharmaceuticals—are embedded directly into the scheduling logic.

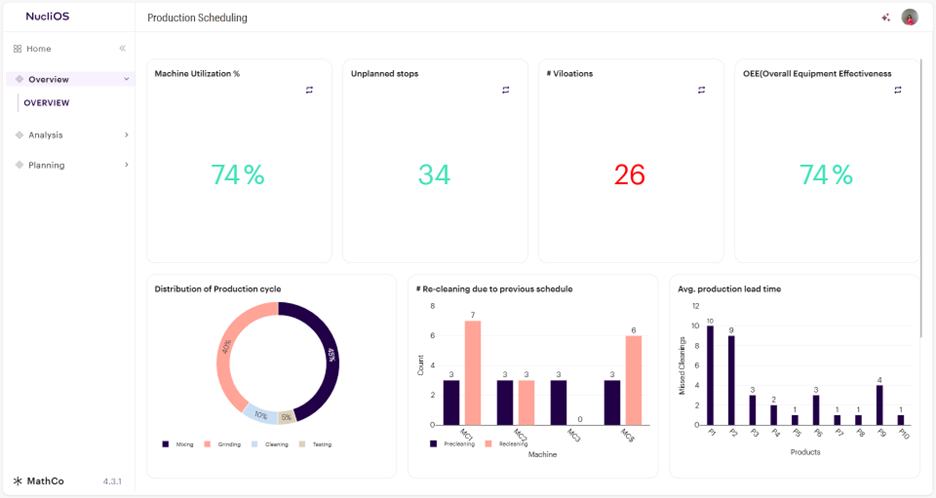

Key Value Adds of the Solution

The scheduling optimization solution delivers tangible benefits across operations and planning teams:

- Hybrid AI with Human-in-the-Loop: AI-driven automation is combined with human oversight, ensuring full transparency, control, and confidence in scheduling decisions.

- Zero Change Management Overhead: The solution integrates seamlessly with existing systems, minimizing disruption from both a technology and user experience standpoint.

- Always-On Scheduling: Schedules are continuously updated based on defined time intervals or operational triggers, ensuring alignment with current conditions.

- Complete Explainability: All scheduling recommendations are fully explainable, with deep integration into existing production systems to support trust and adoption.

Databricks Readiness:

- Metadata-driven ingestion and always-on scheduling accelerators on Databricks Lakeflow to rapidly onboard data from ERP, quality, maintenance, and production systems while preserving lineage, schema evolution, and operational context.

- Agent Bricks–compatible scheduling intelligence solution to continuously sense operational changes, orchestrate schedule re-optimization, surface viable alternatives, and explain trade-offs to planners with human-in-the-loop control.

- Production-grade Databricks operational and FinOps accelerators to support frequent optimization runs with predictable performance, workload isolation, and controlled compute costs

Case Study: AI-Powered Scheduling Optimization for Manufacturing Efficiency

Problem Statement

A leading beverage manufacturer experienced recurring losses from expired inventory and missed delivery commitments, driven by siloed systems, manual planning processes, and limited visibility into manufacturing and supply chain data. Fragmented reporting, unplanned downtime, and poor cross-functional collaboration reduced the organization’s ability to anticipate disruptions and respond in time.

Solution

To address these challenges, MathCo implemented an integrated, data-driven planning and execution platform built on Databricks to unify manufacturing, planning, and operational data. The solution enabled real-time visibility, scenario simulation, and AI-driven decision support using Agent Bricks, empowering teams to proactively manage disruptions, optimize production schedules, and improve operational efficiency and resilience at scale.

Impact

The solution delivered measurable improvements across sites and teams:

- Reduced report generation time from over 6 hours to under 15 minutes per site per day

- Saved more than 6 work hours per site per day, significantly improving planner productivity

- Over 24,000 hours saved annually across all planning teams

- Successfully scaled across 6 manufacturing sites and 18 production planners

Conclusion

Manufacturing scheduling is a high-impact, high-complexity function where even small improvements can yield substantial operational benefits. However, traditional planning systems struggle to keep pace with the dynamic realities of modern manufacturing environments.

By augmenting existing systems with AI-powered scheduling optimization, organizations can improve responsiveness, reduce inefficiencies, and enhance planner productivity—without disrupting proven manufacturing processes. The result is a more resilient, agile, and insight-driven scheduling capability that supports consistent execution in an increasingly complex operational landscape.

The Intelligent Factory: MathCo’s Vision for a GenAI-Driven Manufacturing Revolution